Circular connector locking mechanisms secure mated connections against vibration, shock, and accidental disconnection. Engineers select threaded, bayonet, push-pull, and breakaway mechanisms based on retention force, mating cycles, and application requirements. This article compares their operating principles and performance tradeoffs to guide connector selection.

Operating principles of circular connector coupling mechanisms

Threaded couplings use a coupling nut and mating shell threads that rotate several turns until fully seated to a specified torque. Multi-start thread designs reduce the number of turns while maintaining thread-based retention, and thread engagement distributes mechanical loads across multiple contact surfaces, producing high pull-off resistance. These couplings resist vibration-induced loosening and are used where sealing and mechanical security are critical, such as underwater or chemically harsh environments.

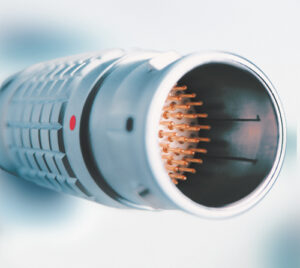

As shown in Figure 1, bayonet couplings use pins or lugs on one connector half and cam tracks on the other. The plug inserts axially, then rotates about a quarter turn until the lugs lock into detents.

Cam geometry converts rotational motion into axial locking force, creating a positive stop that resists back-rotation under vibration. Bayonet couplings provide clear tactile and audible confirmation of engagement with faster mating than threaded designs.

Push-pull couplings use spring latches that snap into a groove on the receptacle when fully seated. Release requires retracting an outer sleeve or actuating a dedicated release mechanism. This design prevents accidental axial decoupling from cable tension while allowing one-handed operation. Axial mating also enables blind-mate interfaces and robotic assembly.

Breakaway couplings are push-pull variants designed to disconnect when axial load exceeds a defined threshold, protecting equipment and users if a cable snags. They maintain a normal latched condition during handling and vibration, releasing predictably at specified forces. Contact retention maintains connector integrity across repeated emergency separations.

Mating cycle durability and wear

As shown in Figure 2, threaded circular connectors typically achieve 500 to 2,000 mating cycles depending on shell size, plating system, and thread design.

Cycle life depends on proper torque application and thread condition, as cross-threading or over-torquing accelerates wear. Heavy-duty connectors with robust thread forms and wear-resistant plating can approach the upper end of this range.

Bayonet connectors deliver cycle performance comparable to threaded designs, commonly rated for 500 to 2,000 cycles. They support faster, more frequent mating in applications where connection speed affects serviceability. Shorter rotation distance and reduced mechanical complexity compared with multi-turn threads can improve cycle consistency when side-loading is avoided during engagement.

Push-pull connectors often support 2,000 to 5,000 mating cycles, with premium medical and military series rated for 5,000 or more. Higher cycle capability reflects shorter latch stroke, controlled wear surfaces, and spring designs optimized for repeated engagement. High-reliability blind-mate modules sustain thousands of mating cycles while maintaining retention and specified pull-off force.

Breakaway push-pull connectors exhibit cycle ranges similar to standard push-pull families, typically hundreds to several thousand cycles depending on release design. These mechanisms maintain contact retention and shell integrity through repeated emergency separations. Cycle requirements should account for both normal mating operations and anticipated breakaway events.

Retention and vibration resistance

Threaded couplings provide the highest resistance to loosening when torqued correctly. Retention derives from thread geometry and applied torque rather than a single pull-off value. Properly torqued connectors resist axial loads and vibration-induced back-rotation more effectively than other coupling types. Self-locking and anti-vibration coupling nuts further improve vibration performance without lockwire or secondary locking hardware.

Bayonet mechanisms deliver high retention through positive lug-in-cam detents, slightly below fully torqued threaded connectors with clear tactile stops. Specifications define pin strength requirements, such as 50-pound load ratings in MIL-DTL-38999 connectors. Cam profiles resist back-rotation under vibration, supporting transportation, aerospace, and heavy-equipment.

Push-pull connectors specify both contact retention and pull-off forces. As shown in Figure 3, high-reliability blind-mate coaxial modules demonstrate retention forces of approximately 18 N and pull-off forces of 90 to 100 N while supporting thousands of mating cycles.

The latch cannot be overcome by axial tension alone, and intentional sleeve actuation is required for release.

Breakaway connectors define engagement forces ranging from a few to tens of newtons, with disengagement thresholds tuned so vibration and routine handling do not trigger release, while higher axial loads do. Contact retention maintains connection integrity through breakaway events, enabling connector reuse. These mechanisms support safety-critical wearable, tool-tether, and tactical applications where controlled disconnection is the preferred failure mode.

Blind-mate capability and connector selection

Threaded couplings offer moderate blind-mate capability. Keyways and polarization features facilitate alignment, though multiple rotations and torque requirements complicate rapid blind mating compared to bayonet or push-pull alternatives. Applications typically favor threaded couplings where maximum retention and environmental sealing dominate, such as aerospace, heavy machinery, and underwater installations.

Bayonet designs provide reliable blind-mate performance through keying features and short rotation after engagement. Quarter-turn operation with pronounced detents supports guided blind mating in rack-and-panel systems. These mechanisms balance speed with vibration resistance in vehicle control modules, rail systems, and bulkhead installations requiring periodic service access under vibration.

Push-pull mechanisms deliver excellent blind-mate capability through axial motion, strong keying, and self-aligning features. Scoop-proof designs and floating receptacle options accommodate axial misalignment during engagement. Applications span medical devices, portable test gear, wearables, and compact military electronics where speed and serviceability are critical.

Meanwhile, breakaway push-pull systems maintain axial, self-aligning characteristics with floating or guided receptacles. They are commonly used in soldier-worn vests and helmet systems, tactical radios, headsets, and safety-critical tethers requiring emergency disconnect capability.

Connector selection by application requirements

Application requirements drive connector selection. These include:

- Maximum retention and environmental sealing: Favor self-locking threaded or bayonet connectors qualified to harsh-environment standards.

- Frequent or blind mating under vibration: Bayonet or breech-lock types that lock within 90°, balance speed, and retention.

- Speed and serviceability: Push-pull or lever-style systems rated for high vibration support rapid, repeatable connections.

- Safety-critical disconnects: Breakaway push-pull systems provide controlled release while maintaining connector integrity.

Table 1 summarizes the typical performance characteristics of the four coupling mechanisms discussed above.

| Coupling type | Coupling speed | Typical mating cycles | Retention and vibration resistance | Blind-mate capability | Typical applications |

| Threaded | Slow; multi-turn engagement | ~500–2,000+ | Highest when properly torqued; excellent resistance to loosening | Moderate | Military and aerospace systems, heavy equipment, underwater, and chemically harsh environments |

| Bayonet | Fast; quarter-turn | ~500–2,000+ | High, positive detents resist back-rotation | Good | Transportation, rail, control modules, rack-and-panel systems |

| Push-pull | Very fast; push-to-latch | ~2,000–5,000+ | High; cannot decouple without sleeve actuation | Excellent | Medical devices, instrumentation, cameras, portable test gear |

| Breakaway (push-pull) | Very fast; push-to-latch | Hundreds to several thousand | Tuned release prevents damage while maintaining contact retention | Excellent | Soldier-worn systems, tactical radios, safety tethers |

Summary

Circular connector locking mechanisms balance retention, speed, and serviceability according to application requirements. Threaded couplings offer maximum vibration resistance and environmental sealing, while bayonet designs provide high retention with faster quarter-turn engagement. Push-pull mechanisms support high mating cycles with excellent blind-mate capability, and breakaway variants enable controlled release for safety-critical wearable and tethered systems. Connector selection should prioritize vibration exposure and environmental conditions, followed by mating frequency, blind-mate requirements, and tool access.

References

Deep Analysis: Differences Between Bayonet, Threaded, and Push-Pull Locking Mechanisms, AMissionTech

What are the Main Coupling Types for Circular Connectors, ConnectorSupplier

Circular Connector Coupling Mechanisms for Extreme Environments, ConnectorSupplier

Circular Push-Pull Connector Products, ConnectorSupplier

Blind-Mating Coaxial Connectors Product Roundup, ConnectorSupplier

Circular Mil-Spec Connector Products, ConnectorSupplier

Circular Connector Ultimate Guide: Advantages, Structure, Types, Pins, Selection, MIL-Spec Picks, ShineIndustryGroup

The Basics of Circular Connectors and Cables, Amphenol LTW

Which Locking Mechanisms for Connectors Should I Choose, RS DesignPark

MIL-DTL-38999 Series Overview, Apollo Aerospace Components

MIL-DTL-38999 Connectors: Performance Ready for all Environments, PEI-Genesis

Key Considerations for Selecting the Right Connector for Rugged Applications, DigiKey

Five Things to Consider When Specifying RF Connectors for Harsh Industrial Environments, ConnectorSupplier

Related EEWorld content

Self-Securing Push-Pull Circular Connectors for Military and Medical Applications

Be Aware of Connector Mating-Cycle Limits

What’s an EMC Connector?

What’s a Thermal Connector?

What Types of Plating are Used on Connectors?